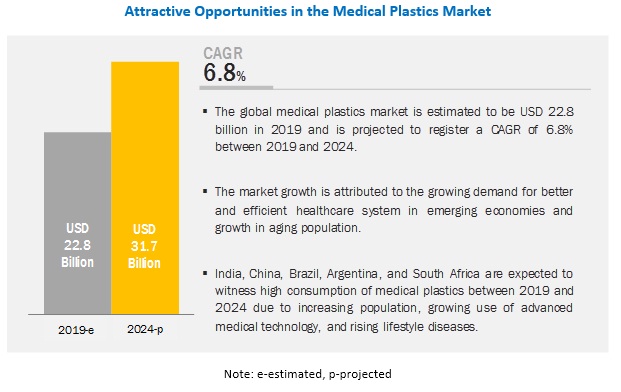

There are many factors that contribute to the rapidly growing medical plastics market. There is an increased demand for advanced medical devices, a rise in disposable income and changing lifestyles, and a demand for affordable and efficient healthcare systems.

These and more are currently driving the medical market, with a current estimated net worth of 22.8 billion USD.

And it is only growing.

Experts suggest that by 2024, the market will grow to a whopping 31.7 billion, with a CAGR of 6.8%.

Source: Markets and Markets, Medical Plastics Market

Applications of Medical Grade Plastics

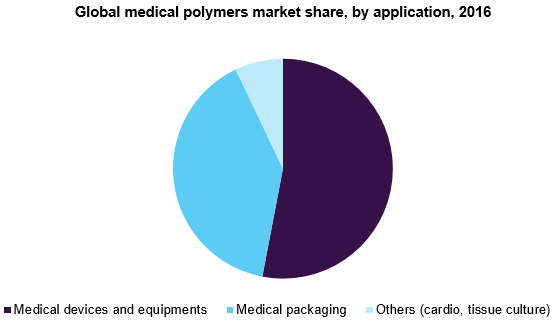

Plastic packaging is widespread across many industries, but no more so than in the medical field. Within the next few years, packaging is expected to grow at a CAGR of 7.8%, due to the increased use in pharmaceutical packaging, device packaging, and more.

Surprisingly though, it is devices such as medical implants and machinery that are generating the largest revenue and driving the industry forward. A perfect storm of an ever-growing population and an increase in chronic diseases, along with the lower manufacturing cost of these devices has led to the largest growth in the medical plastics industry.

Source: Grand View Research, Medical Polymers Market Size

An Industry Standard

Since the 1980s plastics have dominated the medical device industry on account of their low manufacturing cost, flexibility, ease of replacement, and low risk of infection.

Plastics also provide radiolucency, enable light-weighting, and reduce stress-shielding. Because they are radiolucent, polymer-based surgical devices allow surgeons to have an unobstructed view.

All these combine to make medical-grade plastics the gold standard in the industry. Which in turn creates a very lucrative market.

In Conclusion

The medical-grade plastic industry has taken off in an incredibly short amount of time. With increasingly easy to manufacture products coupled with an ever-expanding market, the industry will only get bigger over time. Want to learn more? Contact us today!